OMV Austria Exploration & Production GmbH and its predecessors have been pumping crude oil in Vienna's wine growing region for more than 50 years. oil wells make up Austria's Matzen oilfield. They pump an Approximately 600 oil/gas/water mixture (approx. 90 % water) through pipelines to a centralized live oil collection station. At the station, oil is separated from water and natural gas. The oil is then pumped into the Auersthal tank farm for subsequent processing. Water is directed to the water treatment plant, while natural gas is sent to a compressor station in Auersthal.

Complete renovation

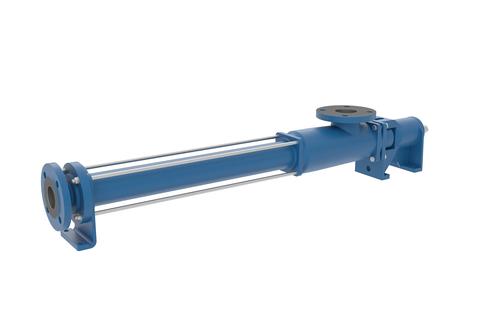

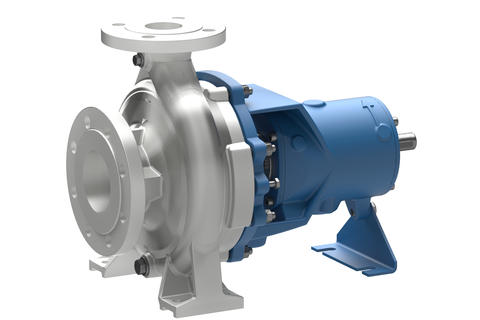

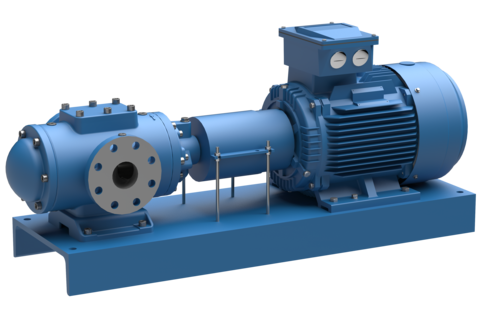

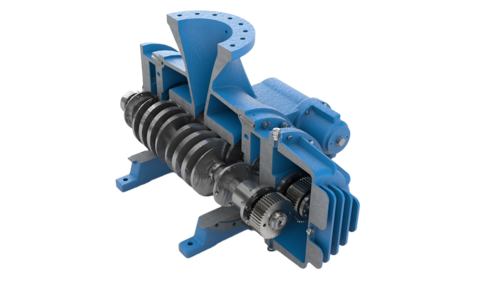

Before the centralized station came on line in 2005, 12 individual extraction stations were in use. In anticipation of pumping crude profitably for another 20 to 30 years, in 2005 the company embarked on a comprehensive renovation of its entire infrastructure, including the network of pumps and 70 km of piping. The system takes advantage of the discharge pressure of the oil wells to pump the oil/water/gas mixture through new pipelines to the centralized Matzen extraction station. The earlier individual stations are now used only as measurement stations for the live oil. Preparation and separation of the live oil now occurs only in the Matzen extraction station. 31 pumps from Allweiler replaced pumps from a variety of manufacturers in the individual stations. The tank farm as weil uses large screw pumps ("SMH" series) from this manufacturer for all qualities of crude oil. These pumps are equipped with frequency converters to control the rate at which the oil is moved through the approximately 25 km long pipeline and into the Lobau reservoir (up to 120 m³/h, max. 40 bar). An Allweiler progressing cavity pump of the AE series moves slop oil (waste water) out of the tank farm.

Between 2005 and 2011, OMV invested € 130 million to completely renovate the collection stations, the extraction station, and the tank farm.