Production Boosted Quickly

The operator wished to complete expansion of the polyester plant within 10 months, requiring rapid pump delivery. Additionally, plant expansion had to occur during ongoing production. Previously installed pumps had to remain in operation while running without changes at high capacity. For this to occur, reliable, safe products with long life cycles, low downtime, and low energy consumption were essential.

The Right Solution

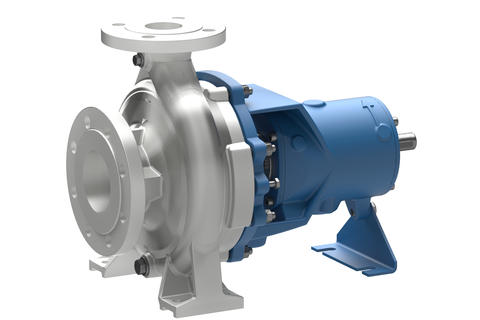

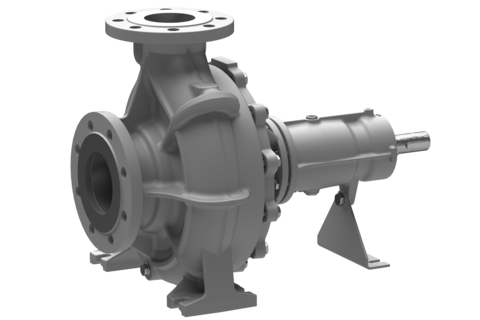

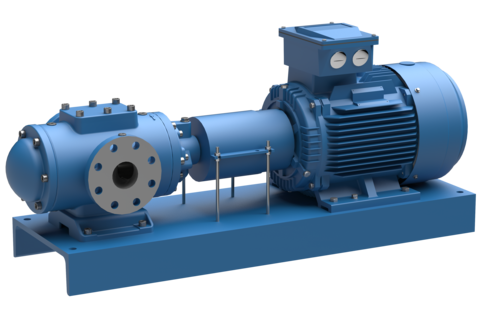

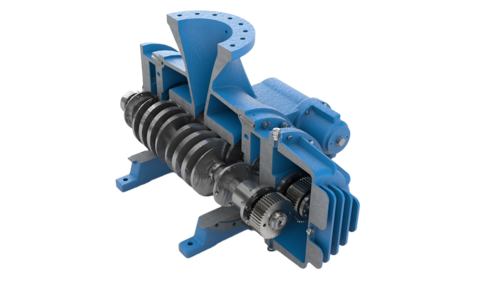

Allweiler worked closely with the plant builder to develop the ideal solution. Chemical pumps of the CNH-B product series (among the largest Allweiler brand standard chemical pumps) were chosen for their extraordinary safety and high quality standards. These pumps are used in many areas of the plant. For example, eight pumps are installed in the PET production area. One-hundred forty glycol pumps and 20 thermal oil pumps are used in the primary and secondary loops of the polyester plant.

During production of synthetic fibers, ethylene glycol reaches temperatures of up to 280 °C, requiring the pumps to be manufactured from 1.4581 stainless steel (a highgrade, heat-resistant material). Special metal bellows-type seals were also designed to work with these high temperatures. Supplemental heating of the CNH-B pumps prevents liquid polyester from solidifying at temperatures below 250 °C. Capacity is 400 m³ per hour at a pressure of approximately 9 bar, with drive power of 180 kW.