Precision Gear Metering Pump Technology

Product Performance You Can Count On.

Precision gear pumps are an integral part of many manufacturing processes requiring metering, mixing, dispensing, coating, and extruding, where accuracy and uniformity of flow are critical. Dive into the unique

design and gain comprehensive insights into their

precise, pulse-free flow.

Definition

What are Precision Gear Metering Pumps?

At Zenith, we believe in providing our customers with precision and consistency by designing and tailoring your metering pump and pump systems to process most applications.

Since 1920, Zenith precision gear metering pumps and systems have provided accurate, reliable and pulse-free metering performance over a broad range of applications like dosing, filling, injection, coating, extruding, and many more! Zenith pumps are designed to handle all kinds of application fluids, be it abrasive‚ corrosive‚ hot‚ cold‚ viscous‚ toxic, or shear sensitive.

As part of the CIRCOR family of brands, Zenith combines exceptional engineering with a focused attention to your needs-from cost to overall product appeal-attention that’s always backed by an experienced support team.

Zenith Pumps

Metering Gear Pumps & Systems for Critical Applications

Key Features:

- Pulse free

- Repeatability and Precision

- High Viscosities, Temperatures, and Pressures

Markets Served:

- Adhesives

- Paints

- Consumer Goods

- Plastics

- Urethanes

- Fibers

- Food & Bev

- Life Sciences

- Chemical

- Power

- Industrial

- Oil & Gas

Applications:

- Coating

- Filling

- Extrusion

- Additive

- Injection

- Dosing

- Spraying

- Spinning

Technology

How do Precision Gear Pumps work?

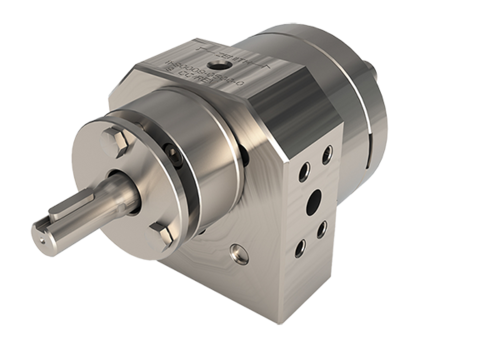

The design utilizes high AGMA standard external spur gears enclosed within a close tolerance housing assembly. This provides you the precise volume of fluid dispensed per shaft revolution. The housing is constructed from a precision ground and lapped three-plate assembly. This assembly is aligned with dowels to allow close control of operating clearances. This construction method in combination with several proprietary internal features is what ensures precise, pulseless and reliable flow under varying process conditions. When Zenith pumps are coupled with a pre-packaged, integrated, closed-loop speed control and a compact motor driver assembly (AC or DC), Zenith is able to provide the most precise and flexible metering gear pump system on the market.

Demanding applications require a precise volume of fluid dispensed – reliably, accurately and consistently. The Zenith precision metering gear pump is the industry standard for true precision metering for challenging applications in a wide variety of industrial processes.

Watch the video to see how precision gear pumps work.

Zenith pumps and systems are used in a range of applications in a variety of markets. Generally, Zenith pumps meter chemical solutions; yet the requirements of each generic metering function can be industry specific. Zenith pumps applications are classified as dosing, filling, injection, coating, extruding, spraying or spinning.

Zenith pumps feature a wide operating flow, pressure and temperature range capable of handling abrasive, corrosive, hot, cold, viscous, toxic and shear sensitive fluids.

- Minimum – Maximum Flow Rate = 0.16 – 27,000 cc/rev

- Maximum Viscosity = 1,000,000 cps

- Maximum Pressure = 4000 psi

- Maximum Temperature = 900F

A general overview of the applications that we participate in is provided below; however, we encourage you to contact Zenith to discuss your specific requirements.

| Application | Markets | Applicable Pumps |

|---|---|---|

| Dosing | General Industry/Pharmaceutical General Industry/Chemical Process General Industry/Pulp and Paper General Industry/Food and Beverage |

B Series H Series 9000 Series |

| Fill | General Industry/Food and Beverage General Industry/Chemical Process |

B Series 9000 Series |

| Injection | Oil and Gas Power Generation General Industry/Fiber General Industry/Plastic Extrusion General Industry/Chemical Process General Industry Pulp and Paper |

PEP II 9000 Series B Series H Series |

| Coating | General Industry/Pharmaceutical General Industry/Food and Beverage General Industry/Chemical Process |

9000 Series B Series H Series |

| Extrusion | General Industry/Food and Beverage General Industry/Fiber General Industry/Chemical Process General Industry/Plastic Extrusion |

PEP II BB PEP 9000 Series H Series |

| Spraying | General Industry/Fiber General Industry/Chemical Process General Industry/Paints |

H Series 9000 Series B Series Flushable |

| Fiber Spinning | General Industry/Fiber | Spin Finish Planetary |

Benefits

THAT GO STRAIGHT TO YOUR BOTTOM LINE

For Accuracy, Reliability Pulse-Free Metering Performance, here are some of their key advantages:

Stable, repeatable flows are assured under varying conditions of temperature, viscosity and pressure.

Unique design offers virtually pulseless flow without valves or flexible elements that add complexities, increase cost and hinder performance.

A variety of pump heads and drive combinations are pre-configured to provide you a range of standard options.

Unparalleled mechanical precision, combined with closed-loop accuracy, ensures exact volume per revolution without expensive flow meters.

Only three moving parts and hardened abrasion resistant materials provide excellent wear, corrosion and self-lubricating performance.

Years of practical application experience, backed by a technical staff with a variety of technical credentials, eliminates the guesswork.

Support

How to choose the right Precision Gear Pump

Due to the process-optimized variety of models, selecting the right precision gear pump requires experience.

Several factors are important:

Fluid properties, operating conditions, environmental conditions, the overall system and applicable standards and regulations.

Finding the right, cost-effective precision gear pump that matches to the process requirements best can be a challenge.

Our team of experts helps to make the right choice.

We will work with you to review your application and determine which pump meets your needs best.

Trusted Brand

Precision Gear Pumps from Zenith

Choosing CIRCOR's Zenith Precision Gear pumps offers many benefits to the customer. The Zenith brands is an industry leader. Being the inventors of precision gear pumps since back in the early 1920s, our brand has millions of installations globally.

Our pumps are designed to deliver maximum performance in a wide range of applications, ensuring versatility to meet diverse customer needs. In addition, our global network of sales and service partners provides excellent customer service, technical support and advice to help customers select the right pump for their needs. This ensures optimal performance. Because we understand the importance of our pumps to our customers' systems, we ensure very long spare parts availability.

MFG in Monroe NC USA

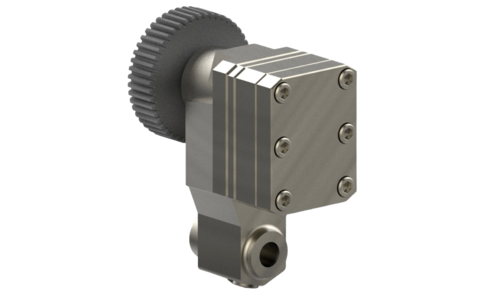

The 9000 series metering pumps are designed to deliver accurate and repeatable flow of metering additives, colorants, hydrogen fuel cell MEA gasketing sealant and adhesive application, or chemicals in a compact and efficient design.

400SS, 316SS, Tool Steel

Max. Pressure [psi] :2,500

Avail. Cap. Range [cc/min] :27,000

Max. Outlet Pressure [PSI] :2,500

MFG in Monroe, NC USA

For chemical and polymer fluid metering applications. B-Series pumps have an “outer drive gear” design that allows pumps to be driven by a common pinion gear or multiple pinion gears on a line shaft.

0.16 - 2.92

Max. Flow Rate [GPH] :8.3

Max. Fluid Temperature [°F] :300

Max. Viscosity [CP] :100,000

MFG in Monroe, NC USA

For polymer extrusion applications where product uniformity is critical. BB PEP Series pumps are specifically designed for medical tubing applications where high precision and ease of disassembly and cleaning are desired.

750

Max. Flow Rate [lbs/hr] :7,000

Max. Fluid Temperature [°F] :950

Max. Dis. Pressure [PSI] :10,000

Materials :Through hardened tool steel, corrosion resistant nickel and cobalt alloys (Stellite)

MFG in Monroe, NC USA

For polymer extrusion applications where product uniformity is critical.

750

Max. Flow Rate [lbs/hr] :7,000

Max. Fluid Temperature [°F] :950

Max. Dis. Pressure [PSI] :10,000