Are you tired of dealing with the complexities of processing and transferring asphaltene and bitumen? Do you want to streamline your operations and save costs in the process? Look no further than IMO Pump rotary screw pumps from CIRCOR.

With decades of experience, IMO Pump has developed hydraulic balanced pumping technology that simplifies the most complex hydrocarbon processing and transfer tasks. IMO Pumps are designed for a range of applications, from asphalt processing and heated storage to railcar, barge, and ship loading and unloading, as well as refinery residuum transfer and storage.

FEATURED PRODUCTS

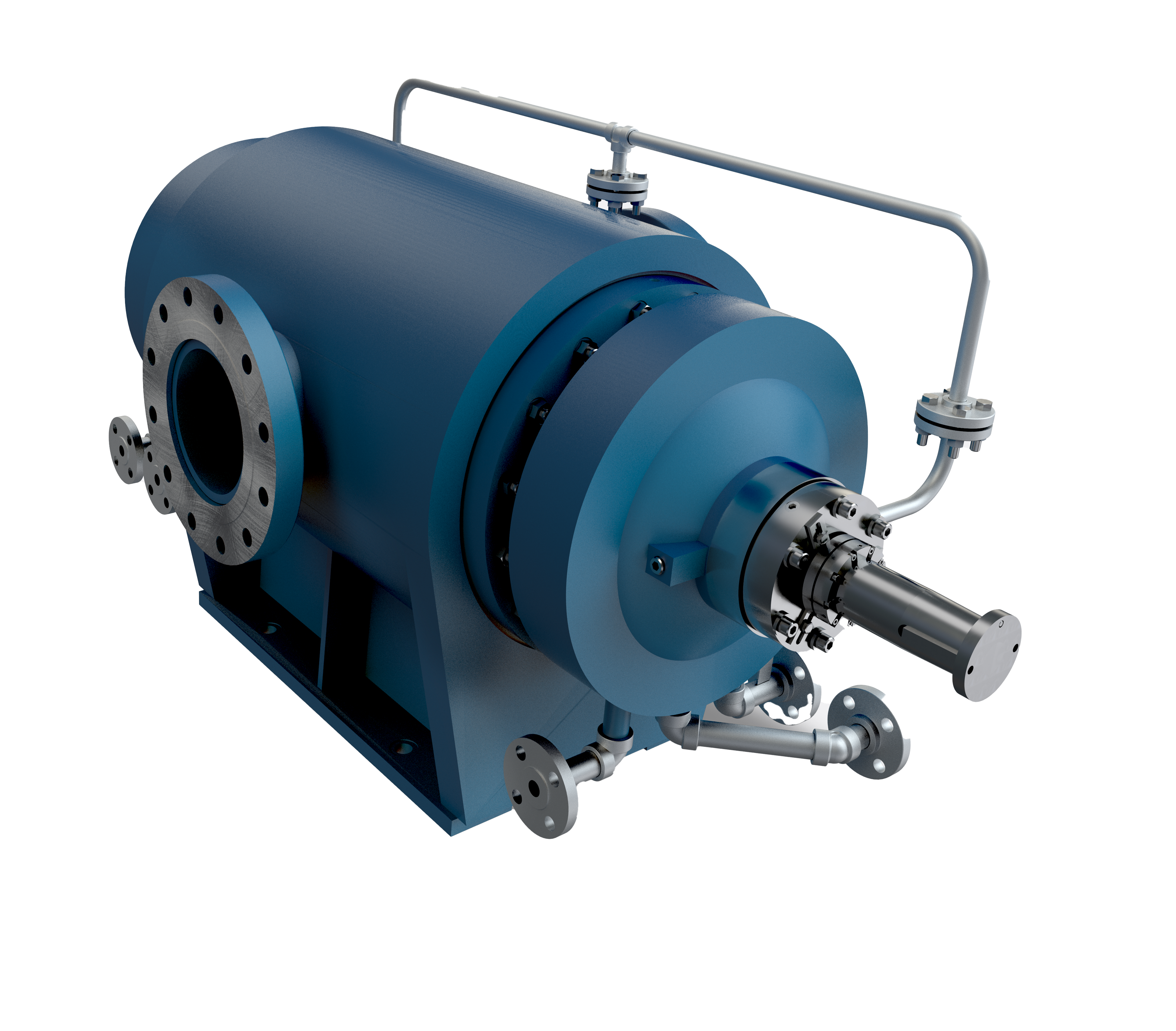

IMO Three-Screw Hydraulic Balanced Pumps

IMO Series Jacketed C324A PUMP

(500 PSI to 900 GPM)

SERIES C324A pumps are of the double suction design. They are inherently in axial hydraulic balance due to the symmetry of the flows. Because this pump series is essentially two pumps operating in parallel, the pumps are very compact for their flow range. 324A pumps are especially suitable for higher temperature operation (asphalts, vacuum tower bottoms, etc.) as there are no antifriction bearings requiring separate cooling. In addition, this series is capable of relatively high speeds making it ideal for steam turbine drive where high speeds improves the efficiency of both the driver and the pump.

Several pump sizes are available in corrosion resistant construction for polymer processing at very high viscosities.

Other units are available in through-drive configurations allowing a second pump or other device to be driven from the end opposite the drive end.

IMO Series Jacketed 323F Pump

(300 PSI to 3,000 GPM)

Contact factory for higher discharge pressures.

SERIES 323F pumps are designed to meet the requirements for a wide variety of applications including highly viscous fluids. hydraulic. lubricating, residual fuel and crude oils. These units have been widely utilized in refineries, chemical and petrochemical plants, lubricating systems and high flow pump boosting stations - wherever high performance and reliability in a rugged design are required.

Typical applications include: Transfer of polymers, chemicals, glycols, vegetable, oils, paraffins, molasses, grease, paint, asphalt and other highly viscous and/or shear sensitive type fluids in pipelines and process systems.

Optional: Steam or Thermal Oil Jacketed

IMO Series 413IC Deepwell PUMP

(100 PSI to 2,000 GPM)

SERIES 413IC pumps are designed for vertical, deep well submerged operation for unloading barges, small tankers or tanks. The pump discharge is axial along the shaft. The design incorporates a third idler rotor which suppresses vibration and noise when pump is lightly cavitated.

IMO 413IC-800JD pump mounted to the end of a discharge column. The drive shaft and spider bearings are inside the column.

Learn more

Features & Benefits

Three-screw Solutions That Work for You

AFTERMARKET

Your best resource for service,

maintenance and quality parts.

No one knows your pumps and systems like the experts at CIRCOR | IMO. Our certified OEM parts are engineered to meet or exceed original equipment standards and our service and support teams are equipped with some of the best knowledge in the industry. We have the resources to troubleshoot, analyze and solve even your most complex issues in ways other service options are unable to.

Contact an Industrial Asphaltenes & Bitumens Application Specialist

THE UPSIDE OF MIDSTREAM PROCESSING Move fluids with speed and precision by having the right people and technology in place. Backed by a team of knowledgeable specialists, CIRCOR terminal station solutions ensure efficiency flows downstream, whether you’re charged with loading and unloading fluids or storing, redistributing and consolidating them.

Three-Screw pumping solutions for LACT applications.