RESULTS

Twelve months without wear, shorter repair times

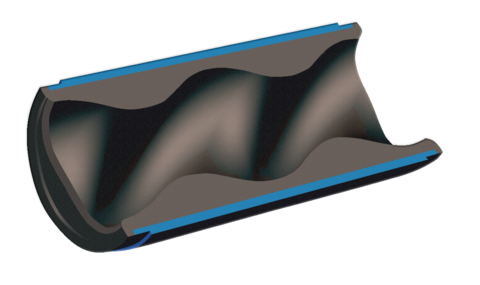

Unlike the previous pumps, Optifix operates completely disturbance-free and reliably. In fact, during the nine-month trial period, no wear was detected. Pump capacity remained uniform at a constant frequency and speed. And this was despite the chemically demanding liquid. In addition to “normal” household sewage, approximately 30 % of the water comes from a large bakery and a producer of fruit juices. This results in a high organic load that must be specially treated with Iron-2 salts before entering the main plant. Even after twelve months of operation, little has changed: Pump capacity of 16 m³/h is precisely on the performance curve without the need to raise speed or frequency.

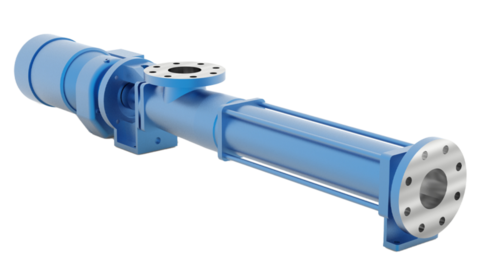

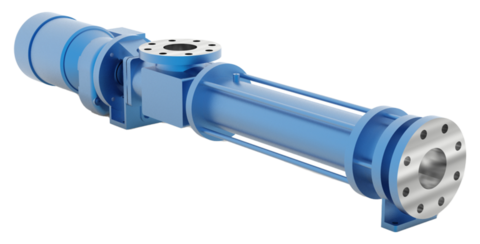

For this reason, the Optifix pump at the MIDEWA plant has not yet been able to show off its latest refinement: When the pump finally needs to be serviced, one person can completely disassemble the pump without removing it from the pipe. Rotor, stator, shaft seals, and joints can be replaced and the pump brought back into service in just 30 to 60 minutes. Allweiler delivers pre-assembled joints, saving time and eliminating tedious work with small parts. Taken together, these refinements reduce average repair time by up to 85 % and extend the pump‘s service life by up to 500 %, according to Allweiler.

“Our goal is to make pumps that you don’t have to worry about. We have achieved this with Optifix,” according to Mr. Geisler. With Optifix, wearing parts can be easily and quickly replaced in five steps, so there is no need to keep extra people in reserve. In Rollsdorf, private operator MIDEWA repairs the pump themselves. This saves money for the association, but only because repairs are rare and are resolved quickly and easily.