Product Search

Search

MFG in Monroe, NC USA

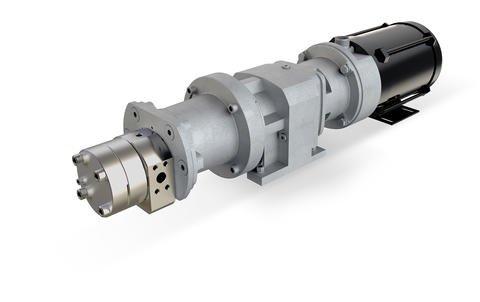

For polymer fluid applications at high temperatures, pressures and viscosities as well as for abrasive fluids.

24,000

Max. Pressure [psi] :4,000

Max. Fluid Temperature [°F] :950

Shaft Seal :Graphoil Packing Seal or Universal Coupling Seal

MFG in Monroe, NC USA

The 9000MD eliminates shaft leakage of hazardous fluids, increases plant safety, and reduces VOC emissions.

No leak

Corrosion resistant :titanium stabilized

MFG in Monroe, NC USA

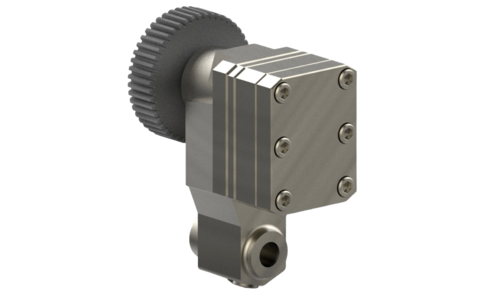

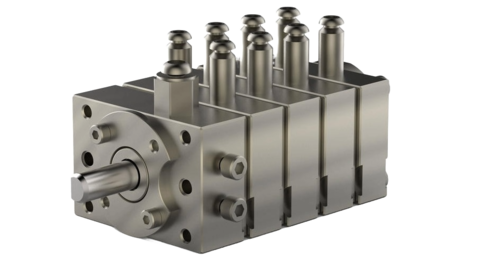

For chemical and polymer fluid metering applications. B-Series pumps have an “outer drive gear” design that allows pumps to be driven by a common pinion gear or multiple pinion gears on a line shaft.

0.16 - 2.92

Max. Flow Rate [GPH] :8.3

Max. Fluid Temperature [°F] :300

Max. Viscosity [CP] :100,000

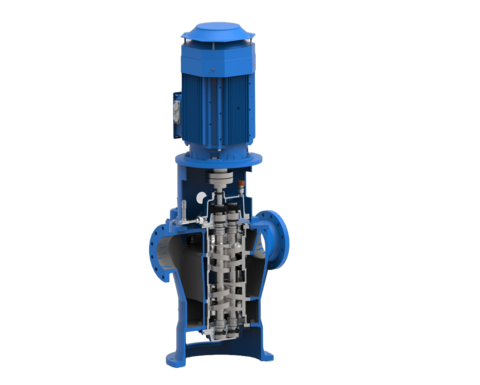

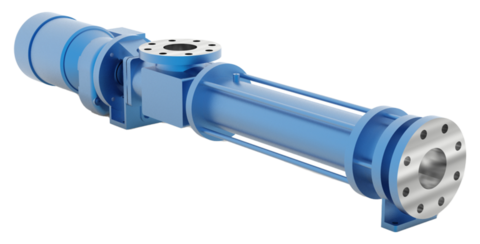

The modular design allows for high production efficiency and flexibility in meeting specific customer requirements. The series covers a wide pressure range up to 48 bar, with special versions for the oil and gas industry exceeding this limit.

7.500

Max. Differential Pressure [bar] :48

Max. Fluid Temperature [°C] :150

Max. Solid Content [%] :60

Max. Viscosity [mPa s] :300.000

Instead of wasting unused energy as heat, the ERCV uses an innovative combination of a volumetric screw-machine and advanced actuator technology to recover unused hydraulic energy.

MFG in Monroe, NC USA

For applications requiring precise multi-stream metering of low viscosity fluids. Commonly used to meter spin finish solutions onto synthetic fiber threadlines.

0.03-1.2

Max. Flow Rate [cc/min] :120

Max. Fluid Temperature [°F] :212

Max. Dif. Pressure [PSI] :100

Developed for multiple pump series, this technology offers incredibly fast disassembly and assembly times and provides best-in-class Mean Time To Repair (MTTR). Suitable for a wide range of fluids.

1.600

Max. Discharge Pressure [bar] :10

Max. Fluid Temperature [°C] :100

Max. Viscosity [mm²/s] :190.000

The solution when it comes to size reduction of solids. They offer unsurpassed performance and efficiency when processing abrasive media, corrosive liquids and solids.

160

Max. Delivery Head [bar] :0,3

Max. Fluid Temperature [°C] :80

Max. Fluid Temperature [°C] :80

Powerful, but also extremely versatile pump series. Whether thinor highly viscous liquids, neutral or aggressive media, gaseous or foaming liquids - our pumps effortlessly master every challenge.

12.000

Max. Differential Pressure [bar] :16

Max. Fluid Temperature [°C] :135

Max. Viscosity [mm²/s] :250.000

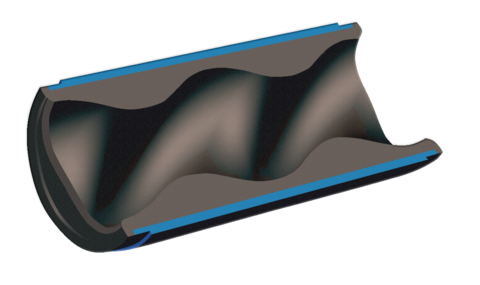

Specifically developed for our progressing cavity pumps with a clear focus on cost effectiveness. The compound formulation is the key to how long a stator will maintain its original flow rate.

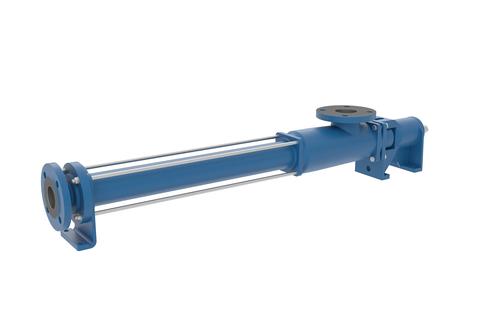

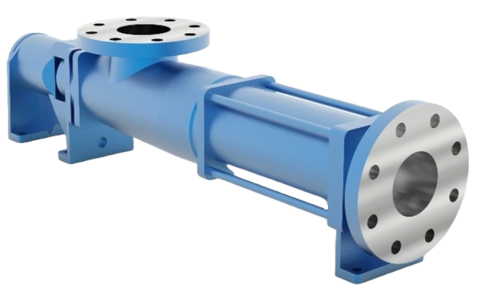

Suitable for the requirements of the chemical and refinery industries. Thanks to the modular design of the pumps, they can be optimally adapted to the specific and demanding requirements.

2.500

Max. Differential Pressure [bar] :40

Max. Fluid Temperature [°C] :400

Viscosity Range [cSt] :0,5-100.000

For pumping clean, lubricating fluids and lube oil applications. The HTN LO pumps provide compact, reliable solutions for high flow requirements in transport and lubrication applications.

1.000

Max. Differential Pressure [bar] :16

Max. Fluid Temperature [°C] :80

Viscosity Range [cSt] :10-760